Food waste and loss are recognized for their economic, social, and environmental impacts. In a 2025 ReFED report, the value of food that leaves the supply chain (“surplus food”) is estimated at $382 billion. This same report highlights 45 food management solutions which were modeled that, if implemented, could yield an annual net financial benefit of $61 billion, collectively.

Many retail food businesses already employ practices that focus on prevention, upcycling, and donations as a part of smart business management, but often those measures are not enough to address all surplus food generated. For companies still left with inedible food products, recycling is a natural next step in responsibly managing these valuable resources by converting them into animal feed, compost, fertilizer, and energy.

However, not all businesses have food recycling programs, and starting one often requires approval from key stakeholders and employees. The following are tips and tricks to help build out your business case for such a program.

Common stakeholders

Before getting buy-in, it is important to know who the stakeholders are in your company, as well as their business priorities and how they relate to recoverable resources. In most companies, there is a delicate dance between corporate and field functions, including but not limited to Operations, Procurement, Merchants, Real Estate, Facilities Management, Corporate Sustainability, Store Employees, and Store Management. Customizing your messaging to fit each person’s role and priorities as you socialize your “food recycling” concept will help build your case.

Did you know?

According to a Deloitte survey, only 38% of employees think their companies are doing enough to implement sustainability measures and combat climate change.

What is food waste?

While the term “food waste” is most commonly used, the concept has shifted. Most companies are already doing everything they can to prevent true waste through prevention, upcycling, and donation. What remains is better understood as inedible food; material that can no longer be eaten or sold but still has value when managed responsibly.

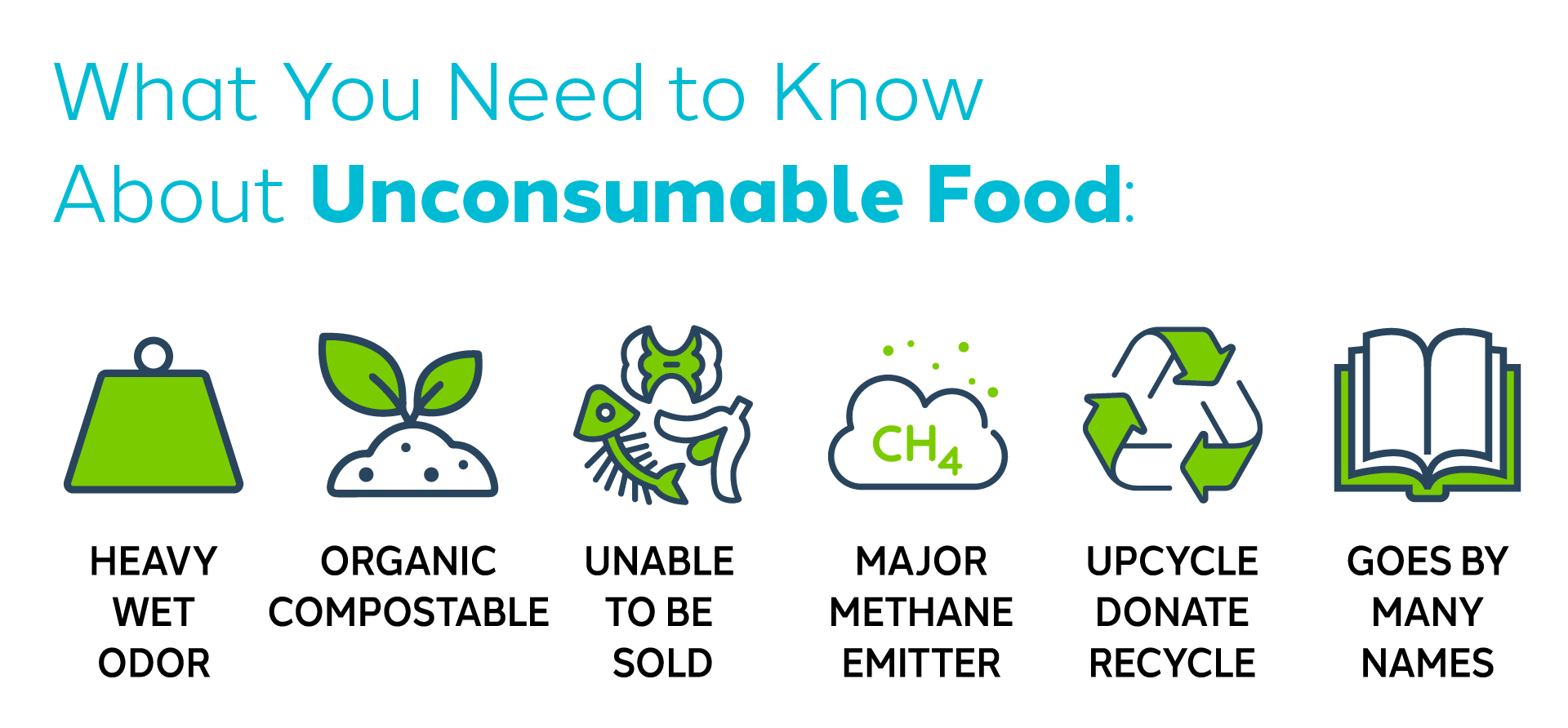

What you need to know about unconsumable food

In building your business case, there are a few nuggets of information to keep in mind:

- It is naturally organic, biodegradable, and compostable.

- It is any food that is uneaten and unable to be sold at the retail level, including expired food products and unavoidable food scraps such as banana peels, egg shells, and bones.

- Unlike other recycled streams, it is usually managed through upcycling, donation, and then recycling.

- When landfilled, wasted food accounts for 58% of all methane emitted from municipal landfills, which are the third largest emitters of methane in the U.S.

- It can also be referred to as organic byproducts, organic material, wasted food, recoverable resources, surplus food, unsold food, food scraps, inedible food products, and – as discussed above – food waste.

- This type of food is heavy, wet, and can have an odor.

Did you know?

Food is the most common material wasted in the United States, making up an estimated 24% and 22% of landfilled and combusted municipal solid waste (MSW), respectively. Literally tons of opportunities to reduce wasted food and recycle more!

Benefits of food recycling

As a champion of food recycling, you’ll need to communicate the advantages of these measures effectively and demonstrate their positive impact on the company.

Here are the key benefits that can help build a strong business case:

- Financial benefits. If your business uses a trash compactor, diverting wasted food to a recycling program reduces expenses associated with food waste, including haul/disposal costs, compactor maintenance, and spill cleanup. Alternatively, if your business uses a trash dumpster service rather than a compactor, you can “right-size” your container, reducing service frequency, which brings down overall expenses. Additionally, if your business pays for a separate meat waste collection service, that can often be eliminated or service frequency reduced because meat is often included as a part of food recycling programs.

- Labor benefits. A food recycling program can reduce the amount of labor and related expenses needed to manage unsold food. This is especially true if employees don’t have to depackage this type of food on-site. The reallocation of time allows employees to focus on more value-added tasks that serve customers, such as increasing food mark-downs, stocking shelves, and customer interactions.

- Food management benefits. Recycling data allows for improved upstream management of food: prevention, upcycling, and recycling. Recycling unsold food is a key part of a comprehensive program to reduce unsold food. Ultimately, recycling data can be used along with other data – for example mark-downs, donations, and trash – to identify patterns and opportunities for improvement. using data to drive upstream reduction will save your business money.

- Compliance benefits. Legislation mandating landfill diversion of unconsumable food is increasing. Eleven states have active recycling mandates or landfills bans specifically targeting food waste disposal and many more are considering it. Implementing food recycling will ensure your business is compliant with current legislation and help you get ahead of future regulations.

- Sustainability benefits. This program contributes to corporate sustainability goals, sustainability initiatives, and ESG reporting. Recycling inedible food products is often part of a company’s goals and initiatives, and it can play a key role in meeting targets, reducing emissions, and being socially responsible.

- Brand benefits. Consumers are increasingly making buying decisions based on a company’s sustainability practices. Adopting these practices can boost your brand value and increase customer traffic. It also positions your company as forward-thinking.

A look at food recycling in practice

If you need real-world examples of the above, we’ve got you covered. When HelloFresh approached Denali for assistance, they wanted to implement an organic material diversion program focusing on pre-consumer surplus food not fit for donation. Together, we were able to convert this inedible food into valuable products like compost and animal feed.

As a result, HelloFresh was able to divert over 4 million pounds of food from landfills. This reduced greenhouse gas emissions equivalent to 278 passenger vehicles not driving for a full year. Talk about a win for sustainability efforts!

Grocers that partnered with Denali to roll out an organic recycling program by implementing our depackaging process saw a 200% increase in food donations, 30-70% increase in landfill diversion, and a 40% reduction in MSW compactor pulls.

Walmart also experienced a labor reduction of five hours per location on average.

Where to start making your case

- Research food recycling programs so you understand how the food recycling industry works, your company’s unsold food management processes, and unconsumable food-related expenses. Look into the EPA’s recently launched Feed it Onward program and perhaps recommend your company join this nationwide initiative.

- Begin talking about this program with colleagues. Determine the key stakeholders and who will help (or hinder) you in this process.

- Educate your colleagues on the food recycling industry and your company’s surplus food management programs.

- Build your business case. Customize your message to align with what is important to each stakeholder.

- Engage a trusted service provider and partner to help you build your business case, and to ultimately provide comprehensive services when you are successful in gaining support.

Did you know?

According to the U.S. EPA and USDA, “Properly managed organics recycling is essential to building a more circular economy for all, encompassing actions that regenerate nature and reducing landfill methane emissions.”

If you are a business that handles food and are interested in learning more about recycling your food byproducts or other organic material streams, contact Denali for more information. We can help you set up a customized program to fit your service needs, organic byproducts, and provide the best value.